How Much Does It Cost To Install A New Alternator Whining

BMW - The Infamous Alternator Bracket Oil Leak on the E6. BMW 7- Series. Alright, I know what you are thinking! Who designs an engine with a hole in it that does nothing, seal the hole with a $5 gasket that leaks, and requires removing several engine components, along with the engine mount, and 8 to ten hours of labor to replace? If you purchased a 2. BMW with an eight cylinder engine and have just found out the dealership wants between $1,4.

Lawyers have opened an investigation into Ford Edge and Flex vehicles over defects with the vehicle’s Power Transfer Units Ford Motor. An Acura Tl Brake Pad Replacement costs between $157 and $340 on average. Get a free detailed estimate for a repair in your area.

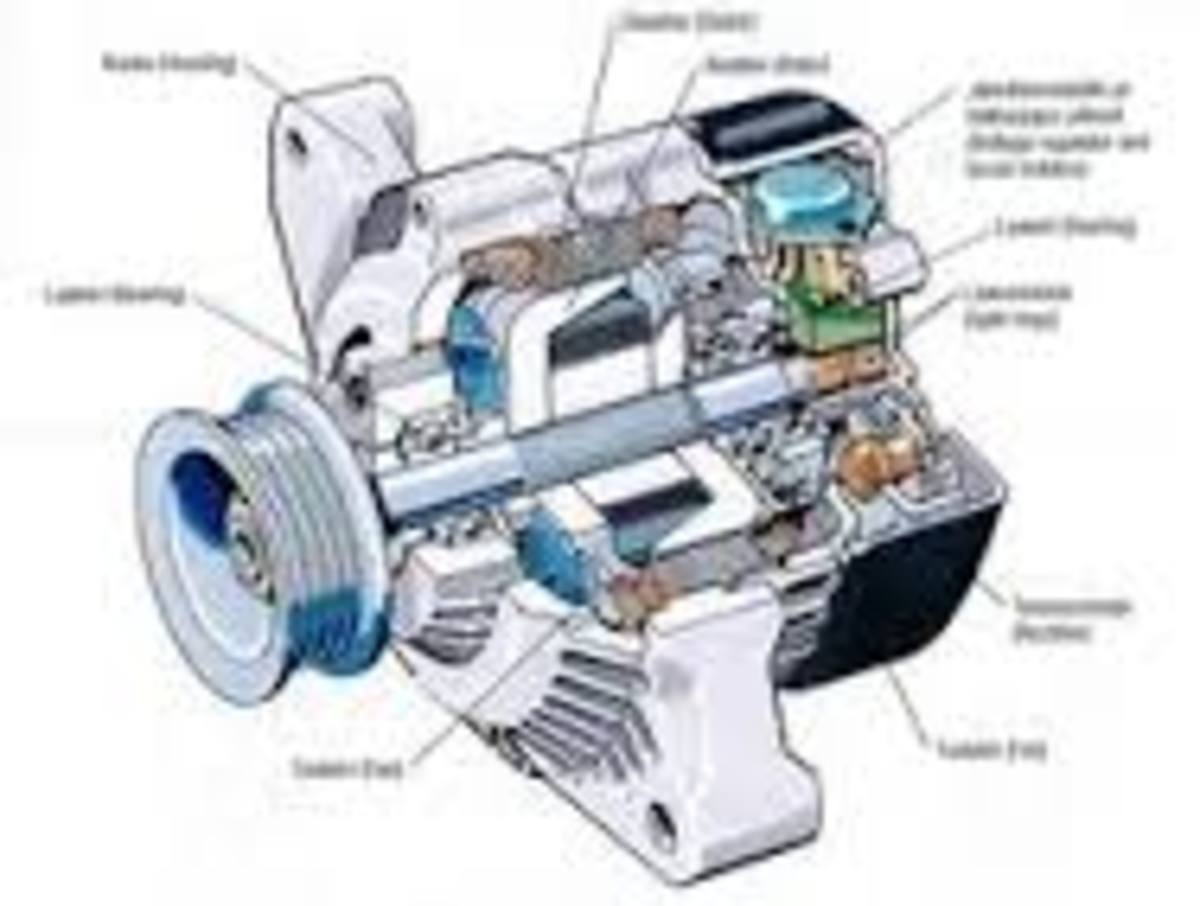

Contents: Alternator Basics; Alternator Ratings; Measuring Capacity Simply; Alternator Whine; Auxiliary Batteries; Farad Capacitors; Battery Isolators; Battery. FREE SHIPPING! This 130 Amp Mustang Alternator is 100% Brand New, not re-manufactured like other companies sell and is tested at the time of assembly.

Seriously, someone had to get fired over this! This is one of the reasons that a car that once sold for over $1. If you are going to do this job yourself, there are a few things you need to know going in. First, you are going to be removing the driver side engine mount, so you are going to have to support the engine. I highly recommend you rent or borrow an engine hoist.

Dexter, If the rear speakers and the sub are powered by the amp and you disconnect the RCA's from the amp, you shouldn't hear anything from those speakers at all.

While you can support the engine from below on a jack, doing so requires removing the dynamic drive, also it is going to get fairly crowded under the car, and if you can lift and support the engine from the top, it will give you more room to work below. If you are saving over a thousand dollars on labor, spend $5. Next, don't be in a rush! You are going to be removing bolts that are in hard to reach places and you DO NOT want to strip them. If you strip them, the engine has to be taken out of the car to fix it, so take your time and work methodically. Warnings aside, if you are comfortable working on your car, have the right tools, and a level place to work you can do this job yourself and save a ton of money. Let's begin. First loosen the driver side tire. Adobe Illustrator Cs4 Multilanguage Incl Keygen Free here.

Safely lift and support the vehicle. Get the vehicle as high as you safely can to give yourself as much room to work as possible.

Please see or article on safely raising and supporting your BMW. Remove the driver side tire.

Next you want to remove the MAF (Mass Air Flow) sensor connector, the air duct and the top of the filter housing. The MAF connector just unplugs from the sensor housing in the air duct, the actual sensor stays in the air duct.

Use a flat head screw driver and loosen the clamp connecting the air duct to the intake duct. Unplug the breather hose going in to the side of the air box cover, squeeze it together and pull it off. Unclip the air boxes two clips and slide the top of the box back and up. Pull the air duct from the intake, taking care that you don't damage the overflow reservoir line or rip the rubber boot connecting the ducts. Leave the actual sensor in the air duct and take care that nothing comes in contact with the sensor surface.

Next you will remove the front cross member covers so you can get the cooling fan and cowl out. On the 7- Series there are eight Torq screws holding the metal plate over the radiator on. Using a T3. 0 remove them and lift the plate off. With the plate off you will see a plastic cover over the radiator and shroud. Use a T2. 7 and remove the five Torx screws holding it on. Unclip the overflow tube and remove the cover. Move to the fan and shroud.

Unplug the two electrical connectors for the AUC and fan motor at the top passenger side. Raise the fan housing up about an inch and fold in the retaining tab on the driver side of the fan housing, this will help it clear the bay. With the tab folded in lift the shroud straight up and out. Remove the drive belt by placing a T6.

Torx socket in the drive belt tensioner. Turn the tensioner clockwise. This will release the tension on the belt and allow you to remove it.

If you are reusing the belt make sure you mark the rotation direction before removing it. There is a small hole on the lower part of the tensioner between the bolt and pulley that you can place a pin into to lock the tensioner in place if you are working by yourself. The belt can be quit stubborn to get on and off at the best of times, let alone if you are trying to do it yourself while holding a wrench on the tensioner. Some Pelican Forum members found it easier to lift the engine before alternator and power steering pump removal. This will give easier access and flexibility when accessing these components. If you try this technique, let us know how it works out. To perform as shown in the article, lifting the engine comes later, after removing the power steering pump.

Now you need to remove the alternator. There are two bolts that hold it to the front of the engine, and two electrical connections on the side. The electrical connects are much easier to get access to and remove if you unbolt the alternator first. Remove the 1. 3mm and 1. Do not let the alternator hang from the cables at any time. You are going to have to remove the power steering pump from the alternator bracket and hang it out of the way. I recommend draining the fluid from the reservoir and disconnecting the line from the reservoir to the pump, but leaving the lines out from the pump to the steering system intact.

Removing the input line from the reservoir will give you more room to swing the pump out of the way and therefore give you more room to work. You are going to be lying under the car at this point and the bracket is behind the pump, so the more room you have to reach in there and work the easier the job will be. It will only take a minute to drain and separate the line and doing so can save you a ton of frustration later. Just do not forget to refill it with new clean fluid, do not re use the old fluid when you put it back together. Begin by using a turkey baster to drain as much fluid as possible from the reservoir, place a large catch pan under the car and have something smaller to catch the fluid that will be in the hose.

It is easier to separate and reconnect the hose from the bottom of the reservoir than from the pump itself. Use a flat head screw driver and loosen the hose clamp, prepare a small catch container to collect the fluid in the hose. Download Do Jogo Dance Dance Revolution Para Ps2 Controller here. I cut the top off a small disposable water bottle and it worked great.

With your catch bottle in hand pull the hose from the reservoir and catch the remaining fluid from the reservoir in the bottle, carefully turn the hose upside down and pour the fluid from the hose into the bottle. With the hose empty remove the two bolts holding the pump to the alternator bracket and engine. Swing the pump out from the engine and tie it and the hoses up somewhere safe out of the way. You will now have access to the alternator bracket. Remove the belt drive tensioner using a 1. You are going to be removing the engine mount so you need to support the engine and have the ability to raise and lower it.

Move back to the top of the engine and remove the top cover. It is held in place by four T2. Torx screws. Remove the screws and pull the cover off the top of the engine. With the cover off you will see the engine lift point (eye hook) at the front of the driver side cylinder bank. Attach your hoist to the eye hook and lift the hoist until it takes the weight of the engine. Move back down under the car to the alternator bracket. There are nine bolts (including the engine mounts) holding the alternator bracket to the engine.

At the front of the engine you will need to remove two 1. T4. 5 Torx bolt. On the side the engine mount is attached to the alternator bracket and engine by four E1. Torx bolts, they are basically female Torx bolts. You will need to get the proper socket to remove these. DO NOT attempt to remove these with anything other than the proper socket, failure to do so may result in stripping the bolts and you do not want to do that. The two bolts on the front are relatively easy to get access to while the ones on the rear are more difficult. You will need an assortment of universal joints and extensions to access the rear bolts through the wheel well.

After you have removed the four bolts holding the mount to the engine, remove the single bolt holding the mounting arm to the mount. Raise the engine enough to remove the mounting arm. There are now two remaining bolts holding the bracket to the engine. Remove the 1. 3mm and 1.