Free Software For Blurry Pictures Of Pretty

I love taking pictures of my plants. Yet sometimes the pictures don't turn out the way I want. I've learned many tricks over the years, and today I would like to.

Pictures of Taig Lathe. Here are pictures of the Taig Micro Lathe and Taig Milling. Taig users machines, modifications. I want pictures! Send me your Taig pictures and I will post them. Mods. projects, even your machine just sitting on the bench.

Last Updated June 1st, 2. Back to the. Taig page. Table of Contents Sections with new additions in Bold type. Bold type. This page can be a bit unwieldy, but you will find a lot of treasures. Face plate angle bracket set. Face plate, 2. 3/4- 1.

A lot of the primo dashboard software requires a paid subscription, which is pretty bullshit if all you want to do is display some tweets next to your calendar.

- Last weekend I purchased some marijuana. Not from some friend of a friend of a friend, but from an actual dispensary in Boulder, Colorado. Boulder, like the rest of.

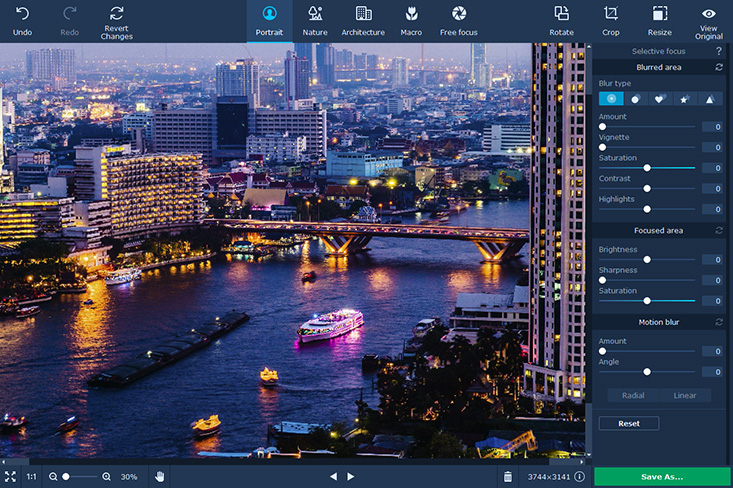

- Out-of-focus photos are becoming increasingly popular, but putting those tacky Instagram filters aside, blurry photos and videos are usually an annoyance. Thankfully.

- Software for video, audio, image converting and editing. Support all popular formats and devices.

- One of the most striking aspects of special relativity is that faster than light travel is equivalent to time travel. This is also one of the most widely understood.

Collet set, collet closer with 8. Jaw 3 1/4. Gashing. Delta drill press table raising. Taig headstock as an index head. The. gear blank set up on the (Atlas 7. Centerpunch. the marks for drilling.

No great precision is required here. Setup. the work to drill holes for tapping (#7 drill for 1/4. Piece was moved along so.

Tapping. the holes with a Makita cordless drill AKA . Cutting. off the nuts to length in the Bandsaw. If you don't have one. Pile of nuts for not much work. Remember this isn't rocket. I'm not working to +/- .

Cutting. length of Al bar for strap clamp. Setup. to cut slot. I took several . 0. Clamping. work to mill table. Closeup. of clamp setup. You can buy a nice set, or.

Little. Machine. Shop. Chris Hendricks sent me an. CD puck. I have to admit it need tweaking.

His drawing and puck can be found in. Nick's. Bar Holder.

Graduated. Carriage Handwheel and Spinner Handle. Foredom. Handpiece Holder. Knurling. Plate on Headstock.

Articulated. Indicator Mount on Headstock. SS Wire with Compound Slide, and Back toolpost Mounted Follower. Work Done on Taig: Flanged Crown Pulley, Bronze Bushing, Knurled Lock.

Knob, Bearing Housing with Internal Retaining Ring. Accessories. Made from #1.

Blank Arbor, Clockwise from Top: 3/8. The form is 1/2. Blank. Trimming. spun form to completed shape with handheld parting tool.

Two. spun halves of prototype birdfeeder parts I prototyped for a local. Emergency'. endmill sharpening using a 4.

Disc. mounted on blank arbor turned down to disc id. Drilling. six indexed holes in train wheel using shop made drilling block.

Makita cordless drill. A. home made stop for a grooving operation using the back toolpost.

Another. view of the same setup. Carving. arbor/Speed lathe made from Taig headstock, I use this for buffing.

How. a tap (held in a tap handle with a centering hole in the end) is used. Taig. The headstock is locked, and the tap turned by hand. Picture. of FROG x- axis CNC setup on carriage. Picture. of FROG spindle speed sensor mounted on adjustable arm 1/8. Step 1, drill a spanner. Center is piece of. Note use. of KENBO quick change tool holder.

Cutoff. toolpost #1. The 2 and 9 are smooth though! Filled. with several coats of black spraypaint, and the top sanded to. A. Neighbor needed a hex cut on an existing steel part that was. This is how I held the part on the Taig mill using a. C Hex Block, 1. 14. ER drill chuck arbor, 1/2 drill chuck and my.

I think it came out quite well.. This. is the bracelet I entered.

Another. Milling the reverse of the logo into a piece of steel. Rolling. silver against the steel . Another. view. And no, I didn't win.. Taig. has changed the Lathe cross slide leadscrew design. It allows. for slightly greater travel and is smoother.

Disassembled. Note that the entire assembly is backwards compatible with older. They only supply these new screws. I tend. to put new pictures at the bottom of this section, and put the.

I. really appreciate pictures, and always welcome new ones, of any Taig. Feel free to email me. CD or regular photographs so I can. If you send me enough, I'll give you your own section on. Alan. Pinkus' Taig setup.

Detail. of Alan Pinkus' motor mount. Don Shaw made this nice bushing with his Taig to.

Jyurki Vuorinen shows. Los. Alamos N. M., this summer: His Spindle, His Lathe Bed.(Don't worry, I sold him another one at cost before he went back to. Finland) Captain AJ made his own boring bar holder. Richie. Richardson Milling a Casting on His New Taig Mill. Another. Roach Modified his Old Craftsman (AA) Lathe to Take a Taig Crosslide. Jaw Chuck. Closeup.

Crosslide. Bruce. Bender has an old shortbed Taig. Another. view, note gearhead motor driving lathe. A. view of the foot at the end of the lathe and the old style tailstock. Martin. Field's Maserati Chassis in 1/1.

Machined with the. Taig Lathe. Another. View of the Chassis, Notice gear selector in lower right. Fritch has his steam engine running!

A. engine made on his Taig lathe. His. version of the Boring Tool Holder. Jack. Sadler's Bow Frog, partially completed. Slide. and Ferrule of the Frog. Bottom. of the Frog. Finished. Biehler's 7x. Taig milling attachment mounted.

Neil. Kempka Uses his Taig CNC Mill to machine plastic components for his. Integrity Instruments. Arbor also serves as 3/8 end mill holder. Quick. change Extension lever for tailstock.

Adapter block was ready made - . Detail. of adapter block - simple channel milled width of tailstock lever.

Clamp. from mill adapter use to prevent slipping of compound. A spare tool. holder or #1. David. Goodfellow made these scotch rods on his CNC mill. Here's. David Goodfellows cribbage board and several stages of construction on.

Taig CNC mill. If I have time I'm going to redo the brass. I took too deep cuts on the lips, and the mill stalled on. I was taking 0. 0. The pegs (6 round. The cover is engraved with my daughter's and her fiance's. Two quarter turn locking handles, one for.

A standard type of. View. Rosing sent a couple of views of his robot: . It turns very nicely, and there's no way I could. The pump itself is 4.

When I first tried the motor. But with the aluminum on there, the heat. The brass. box was soldered, and I got the sides accurate to within a thousandth. I used two Grizzly dial gauges, which. The most important thing was the smooth.

Taig mill bed. Without that, the dial gauges wouldn't have. The people are Grizzly are pretty nice too, good follow up. The holes are all . I suspect it's better than.

I think it's pretty damn amazing! The. stuff I drilled is PETG, a food grade plastic. It has a. protective layer on both sides, and the large bubbles on some holes are. Way easier than copper! My. wife helped me with the camera, it really is pretty amazing to get that. Overall size is .

Pat. Sweeney used Taig parts on his homebuilt milling machine. Tom. Welch mounted a Sherline DC motor on his Taig.

I used a Sherline pulley by putting a blank arbor on the Taig and. I reversed the headstock and put the. Pipe Data Pro Crack Keygen Patch. Taig pulley on the arbor. Then I turned the Taig spindle down to take.

Sherline pulley. That worked great. I got the longest Sherline type. I could mount the motor. I am mounting on the. Index plate. Detent. Another. view of the Detent.

John. Jones first small engines made on the Taig Cylinders are. Crank supports are aluminum.

Crankshafts, pistons and flywheels are turned from. Connecting rods are piano wire with. The drawer knobs are turned. Susan. Parker mounted her Taig Mill quite nicely. I. have mounted on a thick aluminium plate.

I am using a Proxxon. Mill/Drill unit to drive the spindle. 3D Transformation In Computer Graphics Ppt Download App.

I works, but is under powered in. It isn't. quite as big as it looks as it has a fan and shroud - hopefully won't. Proxxon unit. Spec: ELVEN Italy. Chinese import) type EB- 6. B4- B3, 0. 1. 8KW, 0.

HP. 2. 20. Vac 5. Hz, 1. 6. 7A, 1. 50. I used a surplus center. It runs smooth at 3. You cannot stop the chuck at 3. It plows steel off like crazy, rigid taps (and.

I mounted motor and controller underneath. How. about that, an underneath drive taig. Oh, and notice the 1.

Colin. Heath made his version of the Crinz CD puck, out of plastic. Here. is his ! I milled a 1/4. I had to bore the pulley to fit the motor. The mill now is load sensing and. It's like having. Face. milling some 7. I am taking . 0. 15 passes.

I must. also say the spillage face mill is well worth the investment, just a. Jim. Crumley sent this picture of his Taig set up. Tony. Crowe mounted a TOS brand 4 jaw self centering chuck on his Taig. Faced the back and. Turned it around in. Screwed the back.

Then i warmed the. Let the chuck cool.

A. Sandvik 1/4 lathe tool. Jim. Beggerow sent pictures .